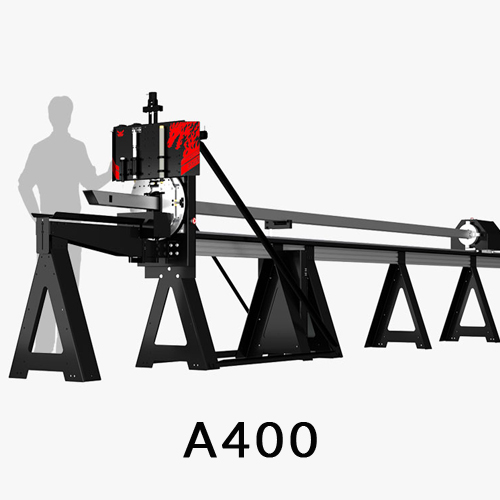

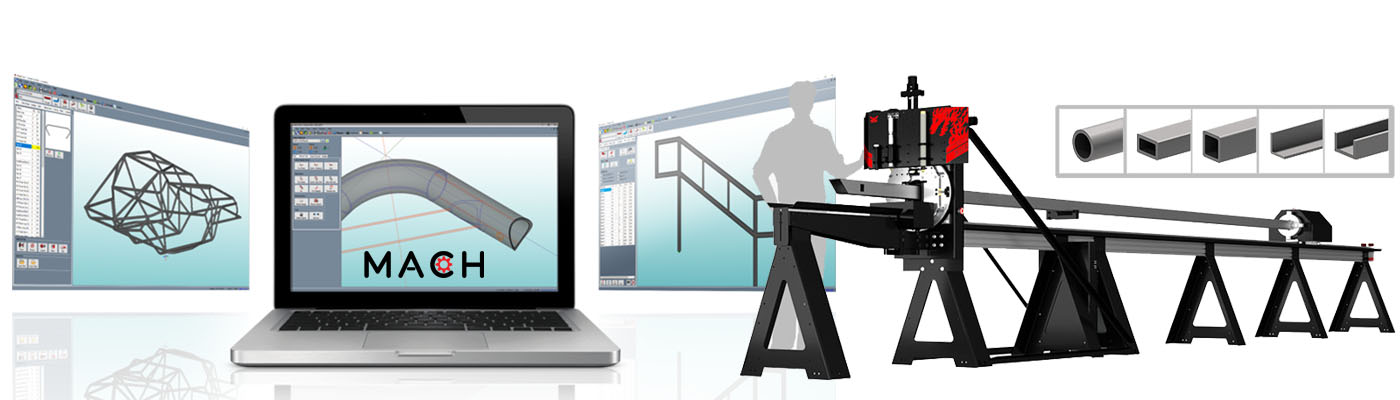

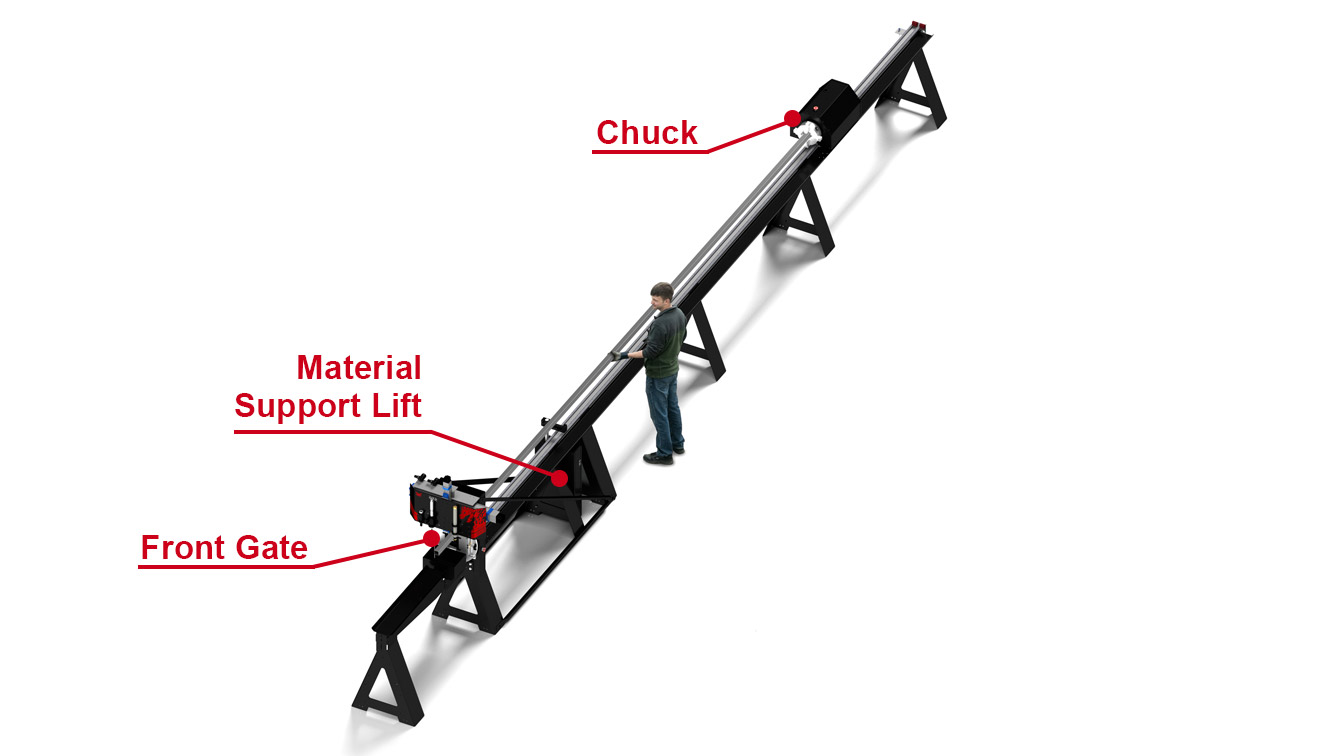

Built to Handle Your Pipe | Tube | Angle | Channel

Length up to | 9m +

-

The Dragon A400 handles full 30 ft. (9m) length material.

-

Our machines can handle up to 150mm Round & Square tubes.

-

Mild Steel | Stainless Steel | Galvanized Steel | Aluminum | Black Pipe | Chrome Alloy

-

Piercing over 12mm wall thickness