CNC Plasma Tube & Pipe Cutting Machines:

Precision & Efficiency for UK and Ireland Fabricators

CNC Plasma Tube & Pipe Cutter with Integrated CAD/CAM Software

In today’s competitive manufacturing landscape across the UK and Ireland, businesses need advanced technology to maintain precision, efficiency, and cost-effectiveness. Enter the CNC Plasma Tube & Pipe Cutting Machines, like the revolutionary Dragon A250. These machines are specifically designed to help fabrication shops optimize their operations by combining powerful plasma cutting technology with integrated CAD/CAM software.

The Dragon A250 is engineered to transform complex CAD/CAM designs into tangible components with seamless accuracy. Whether it’s creating intricate hole patterns or executing precise end cuts, the A250 is your go-to solution for enhancing the production of round tubes and pipes.

Unlocking the Potential of the Dragon A250

The Dragon A250 doesn’t just cut; it marks and simplifies the fabrication process with efficiency and clarity:

- Plasma Cutting for Complex Designs

The A250 leverages plasma technology to cut even the most intricate designs into tubes and pipes. From custom holes to advanced end cuts, this machine provides the flexibility needed for diverse projects. - Integrated CAD/CAM Software

Say goodbye to manual programming. With its intuitive CAD/CAM integration, the Dragon A250 allows you to import designs directly from software, ensuring that every cut and mark is executed to perfection. This feature eliminates costly errors and significantly reduces setup time. - Precision Marking for Bending and Assembly

Beyond cutting, the A250 marks clear instructions directly on the tube, including bend location, rotation, and degree of bend. These markings are vital for ensuring accurate and seamless assembly, improving workflow and reducing rework.

Designed for UK & Ireland Fabricators

Fabricators across the UK and Ireland face unique challenges, including tight deadlines, fluctuating demand, and the need for precise components. The Dragon A250 is designed to address these challenges:

- Enhanced Efficiency

By automating cutting and marking, the A250 allows fabrication shops to handle more projects in less time. This capability ensures that you can meet customer deadlines without compromising quality. - Exceptional Accuracy

In industries like construction, automotive, and metal furniture production, precision is critical. The Dragon A250 delivers consistent, high-quality results, ensuring that your components fit perfectly every time. - Sustainability and Cost Savings

Material waste is a significant concern in metal fabrication. The precision of the Dragon A250 minimizes scrap, saving money on raw materials while promoting sustainability—an increasingly important factor for businesses in the UK and Ireland.

Applications Across Diverse Industries

The Dragon A250’s versatility makes it an ideal solution for various industries, including:

- Construction: Perfect for producing scaffolding, railings, and structural components.

- Automotive: Ideal for creating exhaust systems, roll cages, and chassis components.

- Agriculture: Enables precise cutting and marking of pipes for irrigation and machinery.

- Furniture Manufacturing: Facilitates the creation of custom metal furniture with intricate designs.

- Energy Sector: Suitable for producing pipelines and structural elements for renewable energy projects.

Why Choose Our CNC Tube Plasma Machines?

At [Your Company Name], we understand the specific needs of fabricators in the UK and Ireland. That’s why we’ve partnered with leading manufacturers to provide CNC plasma cutting machines that offer:

- State-of-the-Art Technology: Featuring advanced plasma cutting capabilities and integrated CAD/CAM software.

- User-Friendly Operation: Intuitive controls and software that allow operators of all skill levels to achieve exceptional results.

- Reliable Support and Service: Our local service teams are available to provide installation, training, and ongoing support across the UK and Ireland.

- Custom Solutions: We offer flexible machine configurations to meet the unique requirements of your business.

Key Benefits of the Dragon A250

- Wide Cutting Capacity: Handles a variety of tube sizes and wall thicknesses, providing flexibility for different projects.

- Durable and Reliable: Built to withstand the rigors of daily industrial use, ensuring long-term performance.

- Compact Design: Fits easily into fabrication shops without sacrificing functionality.

- Optimized for Productivity: Designed to maximize throughput while maintaining exceptional quality.

Comprehensive Support Across the UK and Ireland

We’re not just selling machines—we’re offering a partnership. Our team of experts provides full support to help you get the most out of your investment. From installation and setup to training and maintenance, we’re with you every step of the way.

Our strong presence in the UK and Ireland ensures fast response times and localized support, helping you minimize downtime and keep your operations running smoothly.

Elevate Your Fabrication Process Today

Looking to take your tube and pipe fabrication to the next level? The Dragon A250 CNC Plasma Tube Cutter is the ultimate tool for precision, efficiency, and cost savings. With its advanced features and robust support, it’s the perfect solution for fabricators in the UK and Ireland who want to stay ahead of the competition.

Contact us today to learn more about our range of CNC plasma cutting machines. Let us help you find the right solution to meet your production goals and grow your business!

CNC Tube Plasma Machines:

The Ultimate Choice for Light Industrial Fabricators in the UK & Ireland

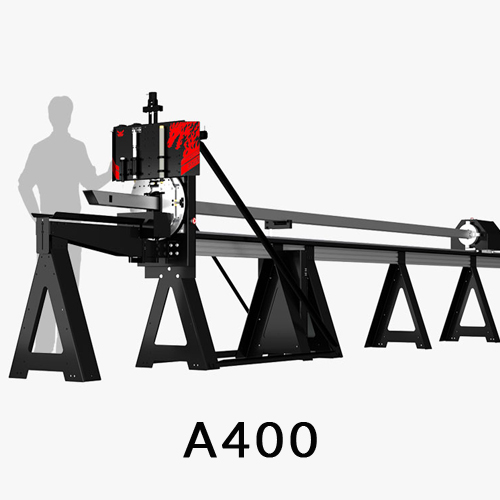

The A400 Dragon: The Most Popular Light Industrial Tube Plasma Cutter

For light industrial fabricators across the UK and Ireland, the A400 Dragon CNC Tube Plasma Cutter is the industry’s top choice. This machine combines plasma cutting, marking, and engraving to transform complex CAD/CAM designs into precise tube and pipe components. If you’re looking for unmatched precision, efficiency, and ease of use, the A400 is the perfect solution to elevate your production capabilities.

The A400: Precision Cutting for Every Tube & Pipe

The A400 Dragon stands out for its versatility and capability, offering the perfect balance between advanced technology and user-friendly operation. Here’s how it works:

- Plasma Cutting, Marking, and Engraving

The A400 brings the power of plasma cutting, marking, and engraving together in one machine. This enables you to create custom hole patterns, end cuts, and detailed engraving on tubes and pipes with extraordinary precision. From simple to complex designs, the A400 does it all, ensuring consistency across every project. - Seamless CAD/CAM Integration

With its integrated CAD/CAM software, the A400 makes transferring your designs from digital files to physical cuts and marks quick and easy. The machine supports a wide range of design formats, meaning you can seamlessly import your files without complicated programming or manual setups. This integration ensures that your designs are executed accurately and efficiently. - Clear Markings for Bending and Assembly

Not only does the A400 cut, but it also marks precise bending instructions such as bend location, angle, and direction. These markings simplify assembly and ensure every component fits perfectly, reducing the chances of errors during the bending process. This makes the A400 an invaluable tool for fabricators looking to improve workflow and accuracy.

Ideal for Light Industrial Workshops in the UK & Ireland

Fabrication shops across the UK and Ireland have different needs when it comes to tube and pipe cutting. The A400 Dragon meets these needs with a combination of precision, speed, and ease of use. Here’s why fabricators love the A400:

- Increased Efficiency

With the ability to cut and mark tubes simultaneously, the A400 drastically reduces production time. Fabricators can handle more projects in less time, improving throughput and helping meet tight deadlines. - High Precision for Every Project

Whether you’re fabricating for automotive, construction, or HVAC, the A400 delivers high-precision results every time. Its ability to execute detailed cuts and markings ensures that your components are always accurate, reducing errors and the need for rework. - Minimal Material Waste

The A400’s precision also helps minimize material waste. Accurate cuts mean fewer mistakes and less scrap material, saving money on raw materials and improving the overall cost-effectiveness of your operation. - Compact and Efficient Design

Despite its high performance, the A400 is designed to fit easily in smaller workshops, maximizing floor space without compromising on capability. It’s an ideal solution for businesses in the UK and Ireland where space is often limited.

Applications for the A400 Dragon CNC Tube Plasma Cutter

The A400 is a versatile machine suitable for a wide range of industries and applications. Here are just a few of the many uses:

- Automotive Industry: Perfect for cutting exhaust pipes, roll cages, and chassis components.

- HVAC Manufacturing: Ideal for cutting pipes and fittings for heating, ventilation, and air conditioning systems.

- Construction: Suitable for producing structural components such as pipes, railings, and scaffolding.

- Furniture Production: Enables custom tube and pipe cutting for modern, industrial-style furniture.

- Energy Sector: Produces precision parts for pipelines, renewable energy projects, and more.

Key Features and Benefits of the A400

- Advanced Plasma Cutting Technology: The A400 is equipped with advanced plasma cutting technology to handle complex cutting jobs with ease and precision.

- Seamless Software Integration: The integrated CAD/CAM software simplifies your workflow by automatically importing and translating designs into cutting paths.

- Durability and Reliability: Built with high-quality components, the A400 is engineered to withstand the demands of daily industrial use, offering long-lasting reliability.

- User-Friendly Operation: With its intuitive interface and simple setup process, the A400 is easy to use for operators of all skill levels.

Why Choose the A400 for Your Fabrication Shop?

Fabricators in the UK and Ireland choose the A400 Dragon CNC Tube Plasma Cutter because it combines cutting-edge technology with ease of use and high precision. Here’s why the A400 is the best choice for your workshop:

- Boost Productivity: Save time and increase your throughput by cutting and marking in one step.

- Achieve Precision: Ensure perfect cuts, bends, and markings for every project.

- Simplify the Process: The A400’s integrated software makes importing and executing designs straightforward and hassle-free.

- Affordable Solution: Get top-tier technology at an accessible price, making it a cost-effective investment for any fabrication shop.

Dedicated Support Across the UK & Ireland

When you choose the A400, you’re not just investing in a machine; you’re gaining a reliable partner. We provide expert installation, training, and ongoing support to help you get the most out of your equipment. With a strong presence in both the UK and Ireland, our service teams are always on hand to assist with any queries or technical issues, ensuring that your operation runs smoothly.

Transform Your Fabrication Shop Today

If you’re looking to boost your fabrication capabilities and stay ahead of the competition, the A400 Dragon CNC Tube Plasma Cutter is the perfect choice. With its advanced features, reliability, and ease of use, the A400 is designed to meet the demands of modern fabrication workshops across the UK and Ireland.

Contact us today to learn more about how the A400 can revolutionize your tube and pipe cutting process. We’ll help you find the perfect solution for your business and take your production to the next level !

CNC Tube Plasma Machines

The Dragon A400 uses plasma cutting, marking, and engraving to make CAD/CAM designs a reality. Any design of holes and end cuts can be plasma cut on the Dragon A400.

The machine marks clear bending instructions such as bend location, rotation, and degrees on the tube. For shops that fabricate with tube and pipe, the Dragon A400 is the essential tool for success.

Ask us to schedule a Virtual Demo today to see live cutting of the Dragon A400.

CNC Plasma Cutting Machine for Pipe, Tube, Angle & Channel

The model 4 has been tested and proven in serious production and high-volume applications, delivering time-savings and material-savings every step of the way. It’s capability for plasma cutting round pipe as well as square, rectangular, angle and channel section, coupled with engraving and marking ability (all standard features) delivers an amazingly versatile solution that will add huge value to any serious fabrication shop!