Our Tube software put simply is the best nesting software in the industry. The proprietary nesting engines, developed and maintained by an expert team of engineers

Seamless Integration of BendTech Dragon Software with SOLIDWORKS

The BendTech Dragon A400 is powered by advanced software that integrates seamlessly with SOLIDWORKS, providing users with a streamlined workflow from design to production. This integration ensures your ideas move efficiently from the virtual design stage to physical fabrication with precision and speed.

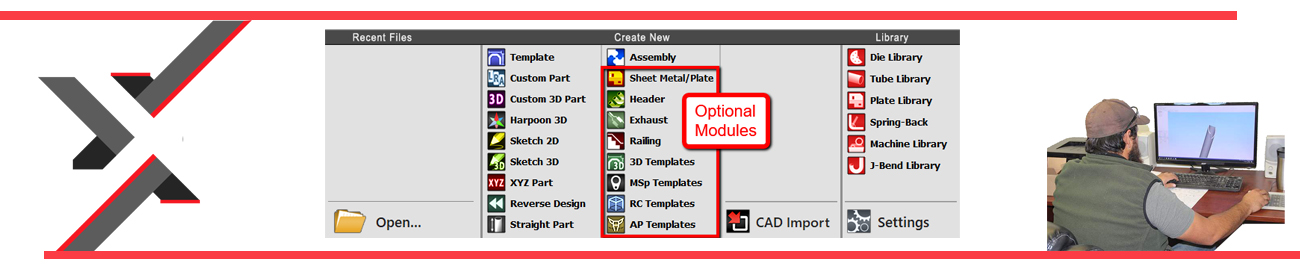

Using SOLIDWORKS, engineers can create detailed 3D CAD models of parts, assemblies, and complete projects. These designs are then imported directly into the BendTech Dragon Software, which translates them into optimized cutting and marking instructions for the Dragon A400 CNC Plasma. This eliminates the need for manual data entry, significantly reducing the chances of errors and saving valuable time.

The Dragon Software intelligently processes the imported files, allowing users to define cutting paths, marking locations, and notching requirements with ease. Its user-friendly interface ensures that even complex designs are handled effortlessly. Additionally, the software provides powerful nesting capabilities, maximizing material usage and minimizing waste.

This seamless compatibility between BendTech Dragon Software and SOLIDWORKS empowers users to maintain accuracy throughout the production cycle. It’s the ideal solution for fabricators, manufacturers, and engineers looking to enhance productivity, improve part quality, and streamline their CNC plasma cutting operations. With this integration, innovation meets efficiency like never before.

Effortless Integration of BendTech Dragon Software with Tekla Structures

The BendTech Dragon A400 is designed to simplify your workflow, and its integration with Tekla Structures offers unmatched efficiency for structural fabricators and detailers. The Tekla Importer within BendTech Dragon Software allows customers to bring 3D models and project data directly from Tekla into the Dragon system, streamlining the transition from design to fabrication.

With this integration, detailed structural models created in Tekla can be effortlessly imported, ensuring every cut, notch, and marking is precisely aligned with the project’s specifications. This eliminates the need for manual measurements and data transfer, reducing errors and saving significant time. The software automatically processes Tekla’s exported DSTV files, optimizing them for the Dragon A400’s cutting and marking capabilities.

The BendTech Dragon Software provides a user-friendly interface where users can customize cutting paths, marking locations, and nesting arrangements. By leveraging the accuracy and detail of Tekla’s models, the Dragon system ensures high-quality fabrication while minimizing material waste.

This seamless workflow between Tekla Structures and BendTech Dragon Software empowers users to handle complex structural designs with ease, improving productivity and precision. For fabricators seeking to enhance their processes, this integration is a game-changer in structural steel and pipe production.

Seamless Integration of BendTech Dragon Software with AutoCAD

The BendTech Dragon A400 enhances productivity and accuracy with its powerful software that integrates seamlessly with AutoCAD, the industry-standard design tool. This integration streamlines the process of turning your AutoCAD designs into precise, ready-to-fabricate parts, saving time and reducing errors in your workflow.

AutoCAD’s detailed 2D and 3D drawings can be easily imported into the BendTech Dragon Software, ensuring a direct transition from design to production. The software automatically processes DXF and DWG files, translating your designs into optimized cutting, marking, and notching instructions for the Dragon A400. This eliminates the need for manual data re-entry, maintaining design fidelity and accuracy throughout the process.

Once imported, the software provides tools to customize cutting paths, define part markings, and arrange nesting for maximum material efficiency. The intuitive interface ensures even complex designs are handled effortlessly, making it easy to manage projects of any scale.

With its seamless compatibility, the BendTech Dragon Software empowers users to fully leverage AutoCAD’s design precision while enhancing fabrication accuracy and speed. For businesses relying on AutoCAD, this integration is an invaluable asset, bridging the gap between creative design and efficient production.

BendTech Dragon Software with Siemens Solid Edge

The BendTech Dragon A400 is designed to integrate seamlessly with Siemens Solid Edge, providing a streamlined workflow from design to production. This powerful combination ensures precision, efficiency, and simplicity for engineers and fabricators working on complex projects.

Solid Edge’s advanced 3D modeling capabilities allow users to create detailed designs with precision. These models can be effortlessly imported into the BendTech Dragon Software, where they are automatically converted into optimized cutting and marking instructions for the Dragon A400. This direct import process eliminates the need for manual data re-entry, reducing errors and saving valuable production time.

The Dragon Software enhances workflow by processing Solid Edge files into CNC-ready formats, enabling users to define cutting paths, notching requirements, and marking locations with ease. It also features powerful nesting capabilities to maximize material usage and minimize waste, making it a cost-effective solution for fabricators.

This seamless integration allows businesses to maintain accuracy throughout the production cycle while leveraging the full power of Solid Edge’s design tools. With BendTech Dragon Software and Siemens Solid Edge working together, you can transform complex designs into high-quality fabricated parts with unparalleled efficiency and precision.